Project Description

Power Pole /Electric Pole For 230KV Power Transmission Line

Geneal Information:

| Product Name: | Power Pole /Electric Pole For Power Transmission Line | |||||||

| Model Number: | 230KV | |||||||

| Brand Name: | Hanssen | |||||||

| Place of Origin: | Yixing,China | |||||||

| MOQ: | 1 container | |||||||

| Price: | Negotiation | |||||||

| Packing Details: | According to customer’s request | |||||||

| Delivery Time: | About two weeks after received customers payment | |||||||

| Payment Terms: | T/T, L/C at sight | |||||||

| Product Name: | Power Pole /Electric Pole | Application: | Power Transmission Line | |||||

| Material: | Q235B (SS400) S355 Q345B(ASTM A572 Gr.50) Q460 (ASTM A572 Gr.65) |

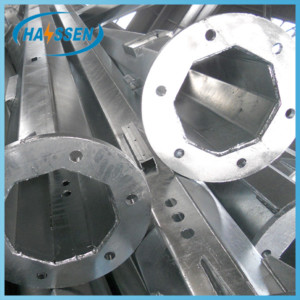

Shape: | » Conical » Octagonal » Tapered round»Polygon |

|||||

| Thickness: | 4mm-30mm | Installation Method: | Frange connection / direct buried |

|||||

| Surface Treatment: | Hot dip galvanization | HDG Standard: | GB/T 13912-2002 or ASTM A 123 |

|||||

| Welding Standard: | GBT 12467.2-2009 / AWS D 1.1 / BS EN 1011-1 |

Connection Method

Of The Pole Shaft: |

Flange connection

or slip joint |

|||||

| Package: | Naked/packed both the top &bottom part with plastic belt ,also can be customized | Service Life Of The Poles: | More than 30 years | |||||

1. Power Pole/Electric pole : With the development of the human society,more and more electric power is needed to support this progress,no matter city or the countryside.The power pole/electric pole is used for carry the electric cable which are transmit the electri power to the factories, hospitals,shopping malls,schools and so on where the electric power is needed.

Normally speaking,the power pole / electric pole mostly used for the electric power distribution from 1okv,13.8kv,69kv as well with normal height is from 25ft to 40ft,also have more higher height from 45ft-90ft which are depend on the project request. Normally,the power pole/electric pole is widely used for Philippines market with huge demand because of the typhoon always broken the electric power distribution every year. People has to replace the broken poles for their development.

We have exported huge quantity of the power pole/electric pole to Philippines for many years experience,and we knows well how to save the cost for our clients and delivery the poles to our clients with very quickly speed. If you want to get more information about that,plz feel free to contact with us now,and we won’t let you down.

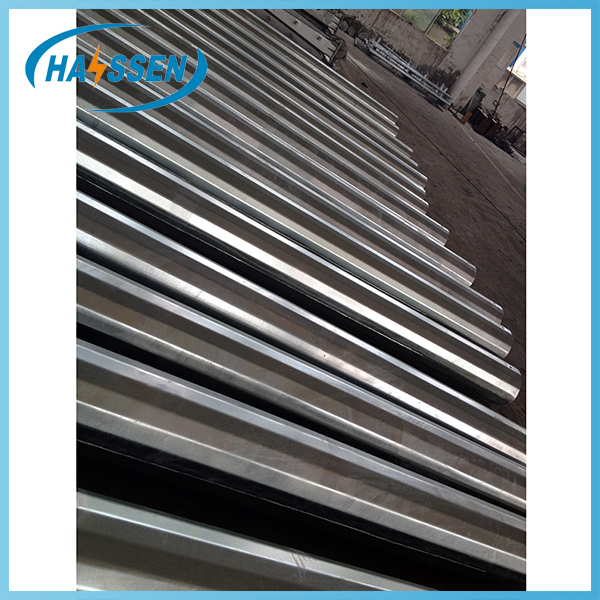

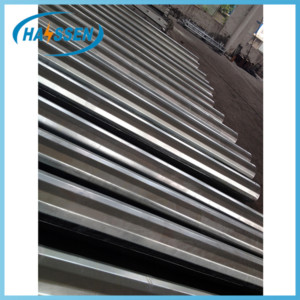

welding line of the power pole/electric pole

Normally,we welding the steel masts with submerge-arc welding and CNC welding with beautiful welding line and good quality,we strickly control the test the welding by the flaw testing with ultrasonic crack detection to make sure there is no crack、undercut、slag inclusion、hole vent for the welding. With the good control,we proud to say that our products always wins our customer’s appreciation for our quality.

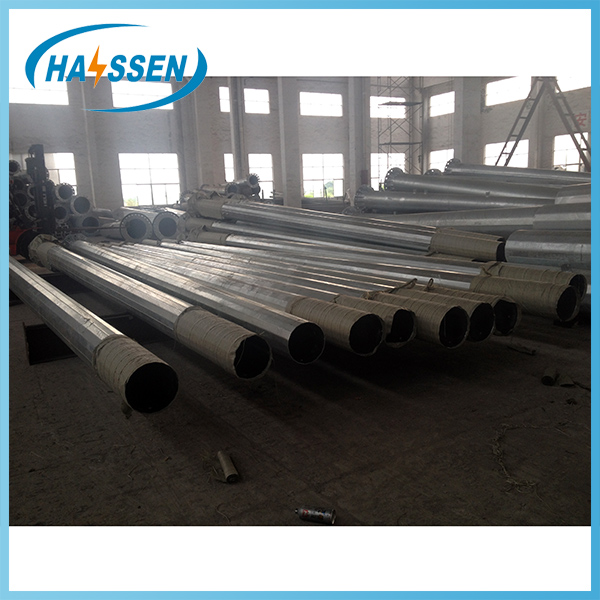

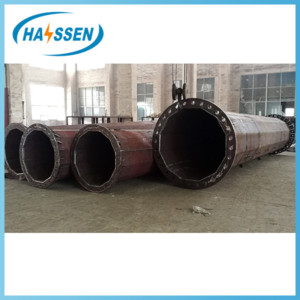

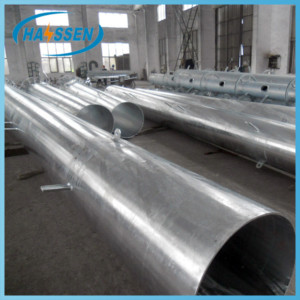

Hot dip gal. of the power pole/electric pole

Standard:GB/T 13912-2002 or ASTM A 123

Both outside and inner side of the steel mast are treated with acid cleaning firstly,then been moved into the zinc pools with more than 450°C temperature completely.At last,the steel mast are finished the galvanization progress for the anti-corrosion disposal after the passivation,phosphorization which can be continually protect the steel mast without corrosion more than 30 years.Our standard for a good hot dip galvanization steel mast is same color of the zinc coating without dent mark,no exposed iron and hang of zinc of defect. Normally speaking,the thickness of the zinc coating is up to the materials thickness.The thicker the material is, the thicker the zinc coating will be.

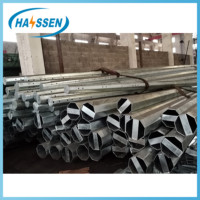

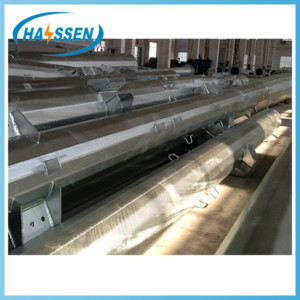

Loading of the power pole/electric pole

- Ater hot dip galvanization,the steel mast should been rechecked for the hot dip galvanization

- Then should been Straightening to keep it’s straightness .

- Remove or repair the steel mast if there’s any defects

- Install the accesseries if there is needed

- Pack the mast accordingly

- Loading for delivery